Have you ever wondered how your car responds to every turn of the steering wheel? Well, the secret lies in the rack and pinion steering system. This essential component plays a crucial role in translating your steering inputs into precise movement, ensuring a smooth and controlled driving experience. Let’s dive into the inner workings of this fascinating mechanism and explore its significance in modern automobiles.

Table of Contents

Steering systems are essential for a vehicle to be driven safely and effectively in the field of automotive engineering. Several manufacturers now prefer rack and pinion steering because of its many advantages. Direct interaction between the driver’s inputs and the movement of the wheels makes for precise and quick handling.

4 types of the steering system:

- Rack and Pinion steering

- Recirculating Ball Steering

- Hydraulic Power Steering

- Electric power steering

Read our previous article to know more about types of the steering system. click on the below link.

4 types of the steering system

What is Rack and Pinion Steering System?

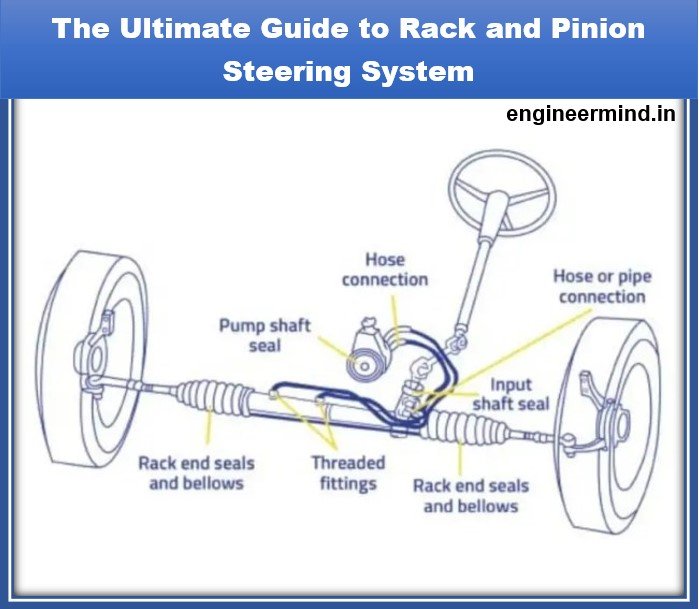

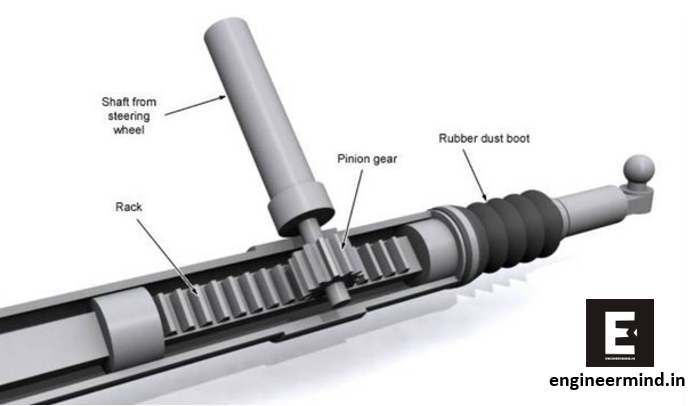

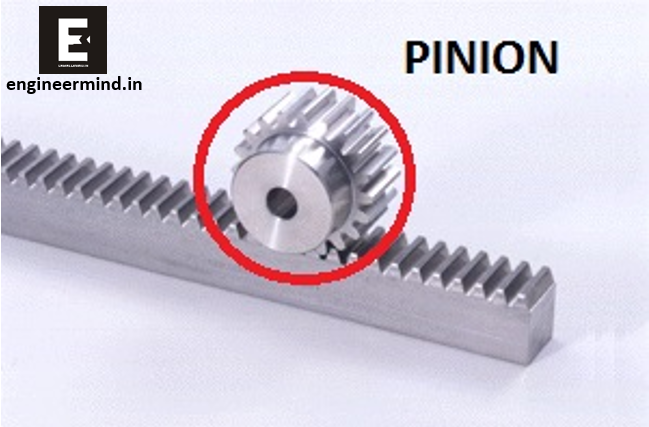

Rack and pinion steering is a type of steering system that converts the rotational motion of the steering wheel into linear motion to control the direction of the vehicle’s wheels. It consists of two main components: the rack and the pinion. The rack is a long, flat gear with teeth that engage with the pinion, a small cylindrical gear connected to the steering wheel.

Types of Rack and Pinion Steering Systems

Rack and pinion steering systems have evolved over time, resulting in different variations to meet varying requirements. The two main types are hydraulic rack and pinion steering and electric rack and pinion steering. Let’s take a closer look at each:

Hydraulic Rack and Pinion Steering

Hydraulic rack and pinion steering systems use hydraulic pressure to assist with steering. A hydraulic pump, typically driven by the engine, supplies pressurized fluid to the steering gear, enhancing the driver’s effort. This type of system has been prevalent for many years due to its reliability and proven performance.

Electric Rack and Pinion Steering

Electric rack and pinion steering systems, also known as EPS, utilize an electric motor instead of hydraulic assistance. The motor is controlled by an electronic control unit (ECU) and provides the necessary power assistance based on various inputs such as vehicle speed, steering wheel angle, and driver preferences. Electric systems offer improved fuel efficiency and flexibility in tuning the steering feel.

Components of Rack and Pinion Steering System

Rack and pinion steering systems consist of several key components that work together to ensure precise control and efficient steering. Understanding these components is essential for gaining a comprehensive understanding of how the system operates. Let’s take a closer look at each of them:

Rack

The rack is a long, flat gear with teeth along its length. It is the main component of the system that converts rotational motion into linear motion. The rack is attached to the vehicle’s chassis and moves back and forth.

Pinion

The pinion is a small cylindrical gear that meshes with the rack. It is connected to the steering wheel, and as the driver turns the wheel, the pinion rotates. This rotation moves the rack horizontally, causing the wheels to turn.

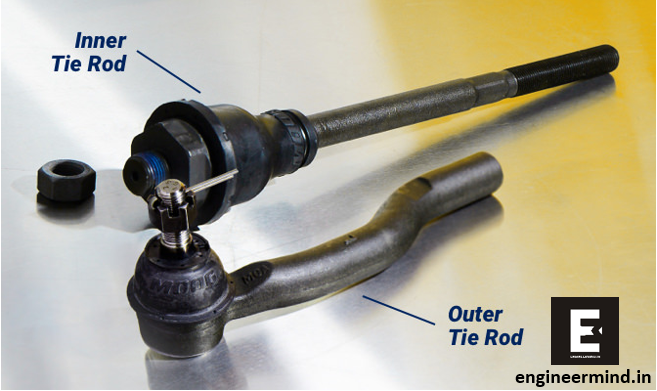

Tie Rods

Tie rods are crucial for transmitting the movement of the rack to the steering knuckles. They connect the ends of the rack to the steering knuckles or steering arms, allowing the wheels to turn in response to the steering input.

Bushings

Bushings are small, usually rubber or polyurethane, components that provide support and reduce friction between moving parts. In rack and pinion steering systems, bushings are used to ensure smooth movement of the rack as it slides back and forth.

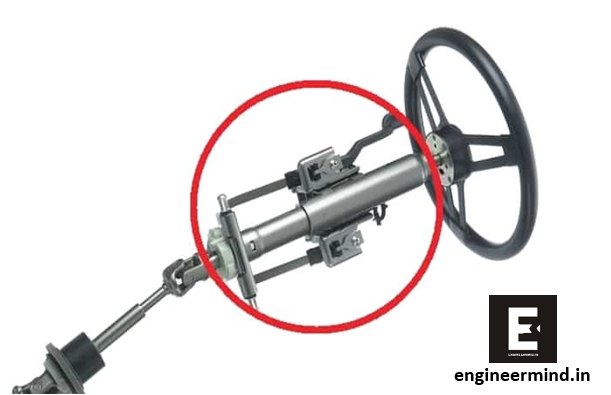

Steering Column

The steering column is a vertical shaft that connects the steering wheel to the pinion gear. It serves as a linkage between the driver’s input and the movement of the pinion, allowing for steering control.

Power Assist Mechanism

In some rack and pinion steering systems, a power assist mechanism is incorporated to reduce the effort required to steer the vehicle. This mechanism can be hydraulic or electric, providing additional assistance to the driver’s steering inputs.

Boots

Boots, also known as bellows, are protective covers that enclose the inner components of the rack and pinion steering system. They prevent dirt, debris, and moisture from entering the system, ensuring its longevity and proper functioning.

Each of these components plays a crucial role in the overall operation of the rack and pinion steering system, working harmoniously to deliver precise steering control and responsiveness to the driver.

How Rack and Pinion Steering System Work?

Certainly! Here’s an explanation of how the rack and pinion steering system works:

The rack and pinion steering system is a mechanism that converts the rotational motion of the steering wheel into the linear motion required to steer the vehicle’s wheels. It consists of two main components: the rack and the pinion.

The rack is a long, flat gear with teeth along its length, while the pinion is a small cylindrical gear connected to the steering wheel. The pinion meshes with the rack, and as the driver turns the steering wheel, the pinion gear rotates.

When the pinion gear rotates, it causes the rack to move horizontally. This motion of the rack is transmitted to the tie rods, which are connected to the ends of the rack. The tie rods, in turn, are connected to the steering knuckles or steering arms that control the movement of the wheels.

As the rack moves, it pushes or pulls the tie rods, which causes the wheels to turn in the desired direction. The length of the tie rods determines the angle at which the wheels turn. For example, when the driver turns the steering wheel to the left, the pinion gear rotates, moving the rack to the left. This action pushes the left tie rod and pulls the right tie rod, resulting in the left wheel turning left and the right wheel turning right.

The rack and pinion steering system provides a direct and immediate connection between the driver’s steering input and the movement of the wheels. This direct linkage enhances the responsiveness and precision of the steering, allowing the driver to have better control over the vehicle.

Some rack and pinion steering systems also incorporate a power assist mechanism to reduce the effort required to steer the vehicle. This mechanism can be hydraulic or electric and provides additional assistance to the driver’s steering inputs, particularly at low speeds or during parking manoeuvres.

Overall, the rack and pinion steering system is a fundamental component of modern vehicles, offering precise control, responsiveness, and an enjoyable driving experience.

Advantages of Rack and Pinion Steering

Rack and pinion steering systems offer several advantages over traditional steering systems, making them a popular choice among manufacturers and drivers alike. Let’s explore some of these benefits:

Responsive Steering

One of the key advantages of rack and pinion steering is its responsiveness. The direct connection between the steering wheel and the wheels provides immediate feedback to the driver, translating into precise control over the vehicle’s direction. This responsiveness enhances the driving experience and promotes safer manoeuvring on the road.

Improved Handling and Control

Rack and pinion steering systems contribute to improved handling and control of the vehicle. The design allows for more accurate steering inputs, resulting in better cornering and stability. Whether navigating tight city streets or cruising on the open highway, the driver can rely on the system to deliver a confident and enjoyable driving experience.

Compact Design

Compared to older steering systems like recirculating ball steering, rack and pinion systems have a more compact design. The reduction in size frees up valuable space under the hood, allowing for greater flexibility in engine placement and overall vehicle design. This compactness is particularly advantageous in smaller vehicles or those with limited engine compartments.

Disadvantages of Rack and Pinion Steering

While rack and pinion steering systems offer many benefits, they also come with a few drawbacks. It’s essential to consider these disadvantages for a complete understanding of the technology. Let’s explore some of the limitations:

Cost

Rack and pinion steering systems can be more expensive to manufacture and repair compared to other steering systems. The complexity of the components, precision engineering, and the need for tight tolerances contribute to the higher cost. However, with advancements in technology and increased adoption, the cost difference has decreased over time.

Limited Steering Feel

Some drivers prefer a steering system with a more pronounced “feel” or feedback from the road. Rack and pinion steering systems, particularly those equipped with power assistance, can dampen the feedback and make the steering feel somewhat disconnected. However, advancements in system design and tuning have mitigated this issue to a great extent.

Potential for Leakage

In hydraulic rack and pinion steering systems, there is a potential for fluid leaks over time. The hydraulic power steering fluid can leak from seals, hoses, or connections, leading to a loss of power assistance and potential damage to the system. Regular inspections and timely maintenance can help identify and address any leaks before they become significant issues.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of the rack and pinion steering system, regular maintenance is essential. Here are a few maintenance tips and common troubleshooting measures:

Regular Inspection and Lubrication

Inspect the system periodically for any signs of wear, damage, or fluid leaks. Check the tie rod ends, boots, and bushings for excessive play or cracks. Lubricate the steering linkage as per the manufacturer’s recommendations to ensure smooth operation and minimize wear.

Common Issues and Solutions

Some common issues with rack and pinion steering systems include power steering fluid leaks, excessive play in the steering, and unusual noises during operation. If you notice any of these symptoms, it’s important to have the system inspected by a qualified technician. They can diagnose the problem and recommend the necessary repairs or replacements.

Evolution and Future Developments

Rack and pinion steering systems have evolved significantly over the years, driven by advancements in technology and the need for improved performance. Future developments may focus on further enhancing the steering feel, integrating advanced driver assistance systems, and incorporating electric power steering in more vehicles to improve fuel efficiency and reduce emissions.

Conclusion

Rack and pinion steering systems have revolutionized the way we control and manoeuvre vehicles. With their precise control, improved handling, and compact design, they have become the preferred choice for modern automobiles. While they come with some drawbacks, the advantages outweigh them, making rack and pinion steering an integral part of the driving experience. Regular maintenance and understanding of the system’s operation ensure optimal performance and longevity.

FAQs

Can I upgrade my vehicle with a rack and pinion steering system if it doesn’t have one?

Retrofitting a rack and pinion steering system to a vehicle that originally had a different steering system can be complex and expensive. It’s best to consult with a professional mechanic or automotive specialist to assess the feasibility and cost of such an upgrade.

Is rack and pinion steering only used in cars?

While rack and pinion steering is commonly used in cars, it is also employed in other vehicles such as trucks, SUVs, and motorcycles. The compact design and improved handling characteristics make it suitable for various applications.

Can I drive my vehicle with a leaking rack and pinion steering system?

It is not advisable to drive a vehicle with a leaking rack and pinion steering system. Fluid leakage can lead to a loss of power assistance, making steering difficult and potentially causing damage to the system. It’s essential to have any leaks addressed promptly to ensure safe operation.

Are electric rack and pinion steering systems more reliable than hydraulic ones?

Both electric and hydraulic rack and pinion steering systems have their advantages and disadvantages. While electric systems offer improved fuel efficiency and precise tuning capabilities, hydraulic systems are known for their reliability and proven performance. Ultimately, the reliability depends on the quality of the components and regular maintenance.

How often should I have my rack and pinion steering system inspected?

It is recommended to have your rack and pinion steering system inspected by a qualified technician during routine maintenance intervals, typically every 12,000 to 15,000 miles or as per the manufacturer’s recommendations. Regular inspections can help identify potential issues before they become major problems.