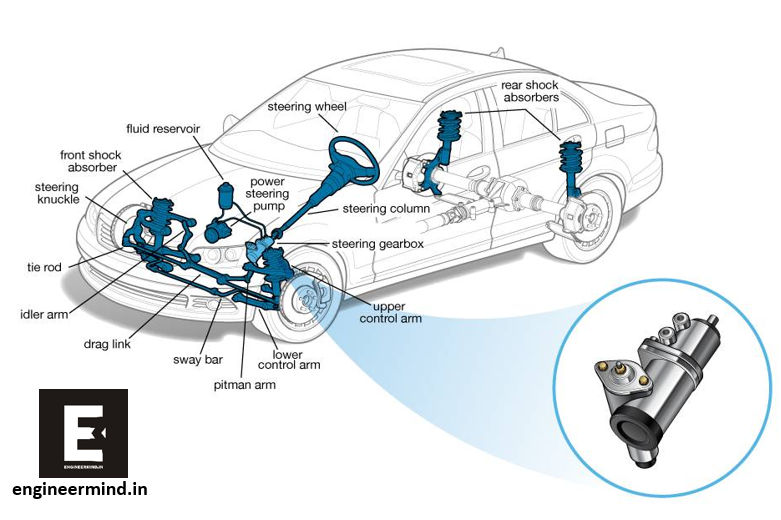

Have you ever wondered what makes your car respond to your every turn with precision and ease? It’s all thanks to the intricate network of steering system components working together seamlessly. From the steering wheel in your hands to the wheels that grip the road, each component plays a vital role in enhancing control and manoeuvrability. Let’s dive into the world of steering system components and unravel their importance. In this article, we will explore the key components of a steering system and their functions.

In the realm of automotive engineering, there exists a symphony of intricate components working harmoniously to ensure the smooth and precise control of a vehicle. Among these, the steering system stands tall as the conductor of this symphony, orchestrating the direction of travel with finesse and precision. Let us embark on a journey to unravel the inner workings of this essential automotive ensemble, focusing our lens on the steering system components that make driving a seamless experience.

Table of Contents

Steering System Components

There are 13 essential steering system components. let’s dive in.

Steering Wheel

At the epicentre of the driver-vehicle interface lies the steering wheel, a timeless emblem of control and direction. More than just a physical interface, the steering wheel connects the driver to the road, translating intentions into action with every turn. Over the years, the design and materials of steering wheels have evolved, offering not only ergonomic comfort but also aesthetic appeal. From classic wooden rims to modern leather-clad designs, the steering wheel remains an iconic symbol of automotive design and functionality.

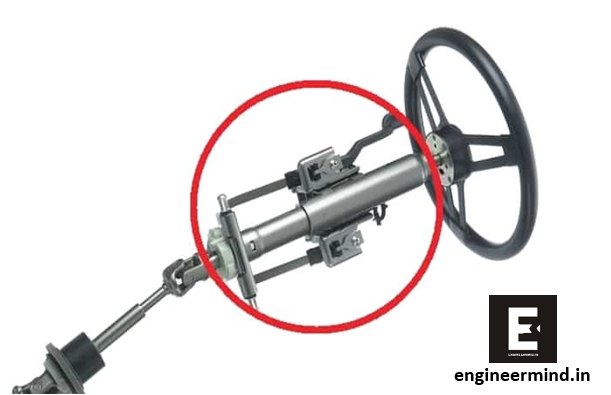

Steering Column

Beneath the sleek facade of the steering wheel lies the sturdy backbone of the steering system – the steering column. The steering column is a vital component of the steering system. Serving as the conduit between the steering wheel and the steering gear, the column houses essential components such as the steering shaft and universal joints. These components allow for smooth rotation of the steering wheel while maintaining a direct connection to the wheels, ensuring responsive handling and control.

Steering Gearbox

The steering gearbox, also known as the steering gear or steering box, is a crucial steering system component. As the intermediary between the steering column and the wheels, the steering gear plays a pivotal role in translating steering inputs into motion. There are two primary types of steering gear mechanisms: rack and pinion and recirculating ball. Rack and pinion systems, known for their simplicity and efficiency, utilize a gear mechanism to convert rotational motion into linear motion, directly influencing the direction of the wheels. On the other hand, recirculating ball systems employ a series of ball bearings to facilitate smooth movement, providing a balance between precision and durability.

Pitman Arm

The pitman’s arm is a crucial steering system component in many vehicles. At its core, the Pitman arm serves as a pivotal point of leverage, translating the rotational movement of the steering gear into lateral motion of the wheels. As the driver maneuvers the steering wheel, the Pitman arm articulates accordingly, exerting force on the center link to direct the wheels left or right. This orchestrated movement is essential for maintaining alignment and synchronicity among the wheels, enabling smooth and precise steering control across various driving conditions.

Idler Arm

The idler arm is a vital component of the steering system found in many vehicles. Despite its unassuming appearance, the idler arm plays a pivotal role in maintaining the integrity and efficiency of the steering system. As the vehicle navigates varying road conditions and directional changes, the idler arm acts as a stabilizing force, minimizing lateral movement and vibration in the steering assembly. By anchoring the center link and providing a fixed point of reference, the idler arm contributes to precise steering control, enhancing driver confidence and safety.

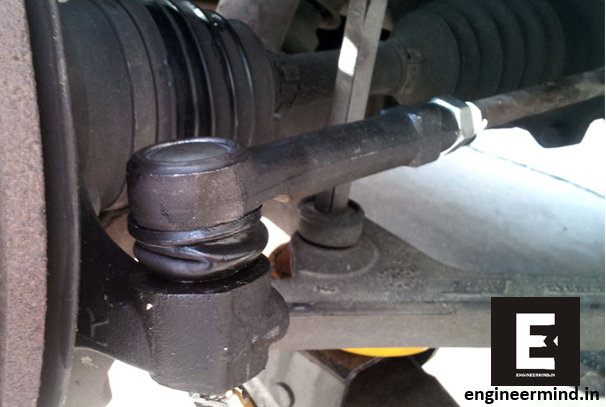

Tie Rod Ends and Linkages

Tie rod ends are critical components of the steering system, these components serve as the final link in the chain, transmitting steering inputs to the wheels and dictating their orientation. Tie rods, in particular, play a crucial role in maintaining alignment and stability, ensuring that the wheels remain synchronized in their movement. Through meticulous design and engineering, tie rods and linkages uphold the integrity of the steering system, fostering confidence and control on the road.

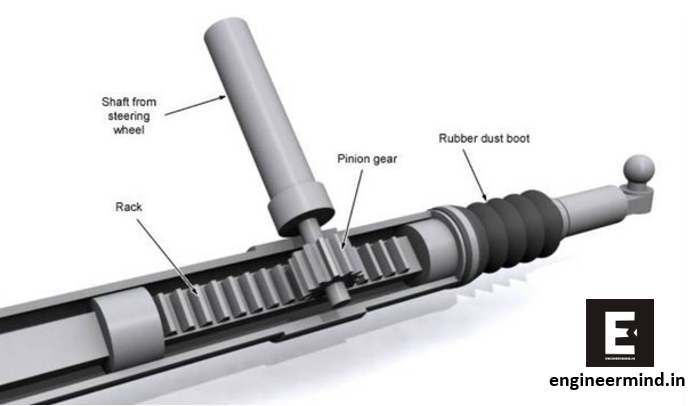

Rack and Pinion

Rack and pinion is a popular steering system used in many modern vehicles. It offers a precise and responsive steering mechanism that allows drivers to have enhanced control over their vehicles.

Rack and pinion steering systems consist of two main components: the rack and the pinion. The rack is a flat, toothed bar that extends horizontally across the vehicle’s chassis. The pinion, on the other hand, is a gear wheel that meshes with the rack.

When the driver turns the steering wheel, the rotational motion is transmitted to the pinion gear. As the pinion gear rotates, it moves the rack either to the left or right, depending on the direction of the steering input. This linear motion of the rack is then translated into the movement of the front wheels, causing them to turn accordingly.

The rack and pinion mechanism provide a direct and efficient transfer of steering input, resulting in a more responsive and precise steering feel compared to other steering systems.

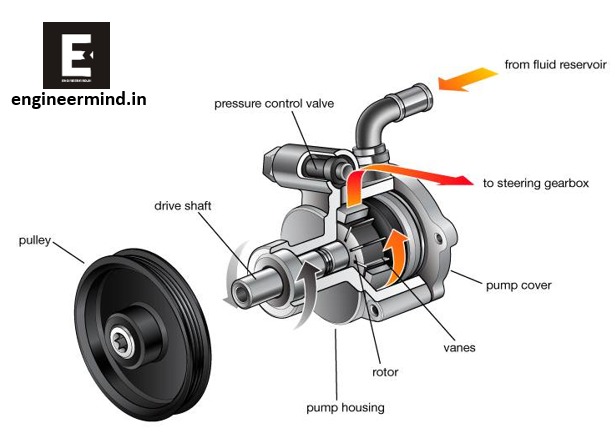

Power Steering Pump

The power steering pump is a vital component of modern vehicles equipped with power steering systems. It plays a crucial role in providing the necessary hydraulic pressure to assist the driver in steering with ease.

The primary function of the power steering pump is to provide hydraulic assistance to the steering system, making it easier for the driver to turn the steering wheel. The power steering pump is typically driven by the vehicle’s engine through a belt or a dedicated electric motor.

When the driver applies force to the steering wheel, a signal is sent to the power steering pump. The pump, powered by the engine or electric motor, pressurizes the power steering fluid and delivers it to the steering gear or rack. The pressurized fluid acts on a piston within the steering gear, reducing the effort required by the driver to turn the wheels.

The power steering pump adjusts the amount of hydraulic pressure based on the driver’s steering input, providing variable assistance according to the driving conditions and speed. This ensures a comfortable and effortless steering experience, whether manoeuvring at low speeds or cruising on the highway.

Power Steering Fluid

A power steering fluid is a specialized hydraulic fluid that plays a critical role in the operation and performance of power steering systems. It is responsible for providing lubrication, heat transfer, and hydraulic pressure to assist in smooth and effortless steering.

Proper maintenance, including regular fluid checks and changes, ensures the optimal performance and longevity of the power steering system. Consult the vehicle’s owner’s manual for specific recommendations regarding power steering fluid type and maintenance intervals.

Steering Knuckle

The steering knuckle, also known as the steering upright or hub carrier, is a vital component in a vehicle’s steering and suspension system. It serves as a connection point between the wheel assembly, suspension components, and steering linkage.

The steering knuckle is typically made of high-strength forged steel or aluminium alloy to withstand the forces and stresses encountered during steering and suspension operation. It is designed with precision to ensure proper fitment and alignment with the wheel assembly and other steering and suspension components.

Ball Joints

Ball joints are pivot joints that connect the steering knuckles to the control arms. They allow for vertical and horizontal movement of the front wheels while supporting the weight of the vehicle. Worn or damaged ball joints can result in steering instability, uneven tyre wear, and compromised handling, making regular inspection and replacement essential.

Steering Dampers

Steering dampers, also known as steering stabilizers or shock absorbers, are essential components of the steering system. They play a crucial role in reducing vibrations, steering oscillations, and sudden jolts transmitted through the steering system.