The clutch is an essential component in manual transmission vehicles that allows the driver to engage and disengage the engine’s power from the transmission system. It enables smooth shifting of gears, controlled acceleration, and deceleration, making it a crucial part of the driving experience. In this article, we will delve into the world of what is the clutch, its types, and how they work.

Table of Contents

What is the clutch?

A car clutch is a mechanical component that is typically used in vehicles with manual transmissions. Its main function is to temporarily disconnect the engine from the transmission, which allows the driver to shift gears smoothly and easily.

The clutch is typically located between the engine and the transmission and is operated by the driver using a pedal located near the brake pedal. When the clutch pedal is pressed, the clutch disengages, disconnecting the engine from the transmission and allowing the driver to shift gears. When the pedal is released, the clutch re-engages and the engine and transmission are connected again, transmitting power to the wheels.

Clutches can wear out over time, especially if they are used frequently or abused (e.g. by riding the clutch pedal, or shifting gears too abruptly). Signs that a clutch may need to be replaced include a slipping clutch, a chatter or vibration when the clutch is engaged, or a burning smell coming from the clutch area.

It is important to note that the clutch is a mechanical component and will wear out with usage, it is generally recommended to replace it after a certain mileage or years of use, depending on the driving conditions and the type of vehicle it is in.

Working principle of a clutch

A clutch’s operating principle is both fascinating and straightforward. Nothing happens in terms of torque or power transmission until the friction plates actually make contact with each other, and this works wonderfully. One plate is attached to the flywheel, and the other plate slides over the crankshaft to act as a clutch. The axial stress on the friction disc is proportional to the applied torque. This means that the axial stress directly correlates to the amount of power transmitted, and vice versa.

The clutch pedal controls the back-and-forth motion of a disc that is splined onto the crankshaft. The pressure plate, which is attached to either many helical springs or a single diaphragm spring, is what does the actual work of applying the load.

A fully depressed clutch pedal will cause the friction disc to retract from the shaft, re-engaging the flywheel. Considering the pressure plate doesn’t exert any axial force, there is no power or torque transmission. Because of this, the motor can keep turning even when the vehicle is stationary.

Moreover, if the clutch pedal is fully removed, the friction disc will advance forward on the shaft, and toward the flywheel. When the disc comes into contact with the flywheel, the mechanism is fully engaged.

How hard one presses on the clutch pedal also affects the amount of force put into action. So, the quantity of power transmitted is proportional to the axial load applied by the pressure plate.

Types of clutch

By engaging and disengaging the shafts of the component that is driving and the component that is being driven, clutches make it easier for power to be transmitted from one to the other. Nevertheless, the mechanism and technique of power transmission change depending on the type of clutch that is used.

Manual clutches

The machine operator is responsible for engaging and disengaging any clutches that are manual. They are appropriate for use in situations in which engagement and disengagement must take place at a predetermined or constant rotational speed.

Hydraulic clutches

To engage and disengage the clutch, hydraulic clutches make use of hydraulic fluid (for example, oil) to extend and retract the pistons that control the clutch. They are appropriate for use in hydraulic systems in which engagement and disengagement operations must take place at a predetermined or constant rotational speed.

Electric clutches

Electric clutches change the form of electrical energy into a form that may be used mechanically. A current is carried through the electrical power source, which results in the formation of an electromagnetic field. Following this, the produced electromagnetic field will attract a pressure plate, which will subsequently engage the clutch. When the power source is no longer able to carry a current, the clutch will automatically disengage. These clutches are well suited for usage in situations in which engagement and disengagement must take place at a particular or constant rotating speed and with a power source that is easily accessible.

Centrifugal clutches

When the correct rotational speeds are reached, centrifugal clutches will automatically engage and disengage. They are suited for applications that need engagement and disengagement at moderate or uneven rotational rates and can be used in a variety of contexts.

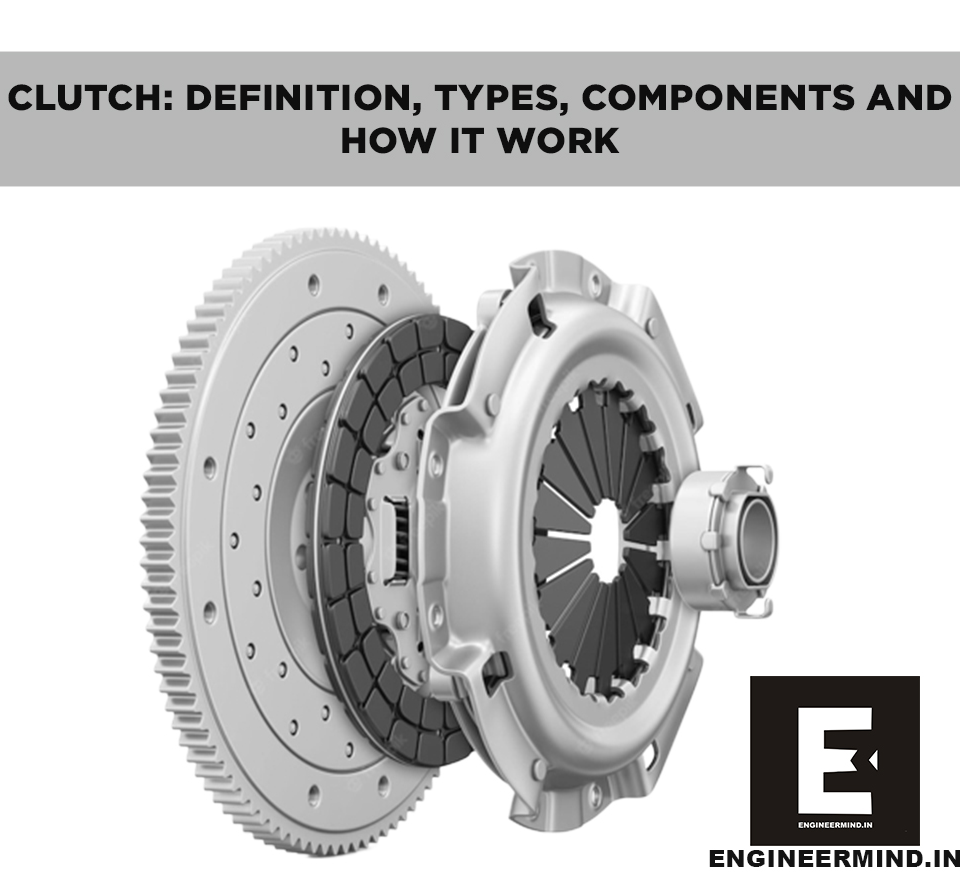

Components of clutch

The main components of a clutch are the pressure plate, Friction Clutch (clutch disc), and flywheel. The pressure plate applies pressure to the clutch disc, which then presses against the flywheel to transmit power from the engine to the transmission. Other components may include a release bearing or fork, and a pilot bearing or bushing.

Flywheel

As long as the engine is running, this clutch component, which is located on the crankshaft, will function. The flywheel has a friction disc located on the outside. A flywheel is a mechanical device that is typically connected to the crankshaft of an internal combustion engine and is used to smooth out the power delivery from the engine to the transmission. The flywheel stores rotational energy, which helps to keep the engine running smoothly during gear changes. It also helps to reduce the amount of power lost during the combustion process. In addition, flywheels are also used in some types of machinery and equipment to smooth the operation and provide a consistent rotational force.

Friction disc

A friction disc, also known as a clutch disc, is a component of a clutch system that transmits power from the engine to the transmission. It is typically made of a metal plate with friction material bonded to one side. The friction material can be made of various materials such as ceramics, and organic or metallic composites. The clutch disc sits between the pressure plate and the flywheel, and when the pressure plate applies pressure to the disc, it presses against the flywheel to transmit power to the transmission.

The clutch disc also plays an important role in the clutch system by allowing the driver to engage and disengage the engine from the transmission. Depending on its use, the friction disc may consist of one or many discs. It is constructed from a substance having a high coefficient of friction. On a drive shaft, the friction disc is placed.

Pressure plate

There is another friction disc on the pressure plate. The splined hub is where this pressure plate is mounted. The pressure plate is a component of a clutch system that applies pressure to the friction disc in order to transmit power from the engine to the transmission. It is typically made of a metal casting and is bolted to the flywheel.

The pressure plate has a spring-loaded mechanism that, when engaged, pushes the friction disc against the flywheel, creating friction that allows the engine to power the transmission. When the clutch pedal is depressed, the pressure plate is disengaged, releasing the friction disc and allowing the engine to spin independently of the transmission. This allows the driver to shift gears.

The pressure plate can be of two types:

Single plate Clutch

It uses a single pressure plate to press the friction disc.

Multi-plate Clutch

It uses multiple pressure plates to press the friction disc. These types of clutch are commonly found in high-performance cars as they can handle more torque.

How Clutch Work?

However, not everyone is aware of what a clutch is or how it operates, despite the fact that everyone is aware that a car is powered by an engine. This mechanism is responsible for both engaging and disengaging the power transmission that runs from the driving shaft to the driven shaft in your vehicle.

It is possible for your vehicle to have two or more of them connected to the spinning shafts under the hood. When driving a vehicle with a manual transmission, the clutch will be connected not only to the shaft that comes from the engine but also to the shafts that turn the wheels. Even if the motor is going to be turning nonstop, you do not want the wheels to be in a perpetual state of rotation.

A clutch allows the driver to engage and disengage the engine from the transmission. When the clutch is engaged, the engine and transmission are connected and the wheels of the vehicle will turn as the engine runs. When the clutch is disengaged, the engine and transmission are not connected and the wheels of the vehicle will not turn even though the engine is running.

The clutch system is made up of several components: the flywheel, the pressure plate, the friction disc, and the clutch release mechanism. The flywheel is attached to the crankshaft of the engine and the pressure plate is attached to the flywheel. The friction disc sits in between the flywheel and the pressure plate.

When the clutch pedal is depressed, the release mechanism disengages the pressure plate from the friction disc. This allows the engine to spin independently of the transmission. When the clutch pedal is released, the release mechanism engages the pressure plate with the friction disc. This connects the engine to the transmission and the wheels of the vehicle will turn as the engine runs.

The friction material on the clutch disc and the pressure plate work together to create the friction needed to transmit power from the engine to the transmission. The strength of the spring in the pressure plate and the amount of pressure applied to the friction disc can be adjusted to fine-tune the clutch’s engagement point and feel.

In summary, the clutch works by allowing the driver to disconnect the engine from the transmission, allowing the driver to shift gears smoothly, and then reconnect the engine to the transmission to transfer power to the wheels of the vehicle.

Here are five signs that your clutch needs replacement:

- Difficulty changing gears or gear ratios.

- A noise that resembles squeaking or groaning when the clutch pedal is depressed.

- A clutch pedal that is spongy, sticky, vibrating, or otherwise loose when it is pressed.

- Capability to crank the engine while having weak acceleration.

- Letting the clutch slip, which results in a short reduction in acceleration.

Conclusion

Clutches play a vital role in manual transmission vehicles, enabling smooth gear shifting, controlled acceleration, and efficient power transfer. Understanding the types of clutches and how they function provides valuable insights into the mechanics behind this essential automotive component. Whether it’s a single-plate clutch in your everyday car or a multi-plate clutch in a high-performance vehicle, the clutch ensures a seamless driving experience. With this knowledge, you can appreciate the intricacies of clutch operation and the crucial role it plays in the overall performance of a vehicle.